Pipe Installations

Compressed Air – Distribution

The distribution system is the most critical part of a compressed air system. Experience has shown that once a compressed air distribution system is installed it is never removed but frequently extended and changed.

Pressure Drop:

Pressure drop in a system is achieved by simply using insufficient pipe diameter or by reducing pipe diameters from large to small towards the extremities. “Saving” on regulators is a misconception and grossly unfair to the customer. Such a system is handicapped from the start.

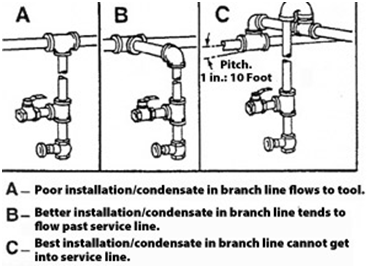

Conventional distribution systems are sloped downwards in the direction of flow, with usage points being taken off the top side of the distribution system with a goose neck arrangement. Condensate drain legs are fitted to the bottom side of the distribution system

Gate valves are often used in compressed air systems. These valves easily leak air at pressure through their throat and at the stem and gland seal assembly and are more intended for water use. Ball valves are better suited for compressed air systems.

With Compressed Air Products’ compressed air distribution technology, compressed air lines are installed horizontally with a ring main layout and a generous amount of isolation valves mounted at strategic points, dimensioned for full pressure and full flow right through to the extremities

Significant long term benefits are derived by this system as air treatment and maintenance on the system, and maintenance on applications are reduced significantly. In cases up to 90% savings on maintenance costs have been achieved.

Materials

Materials used for compressed air distribution systems vary according to environmental conditions, cost, size of installation, pressure of system, flow capacity, type of application, method of construction, and choice.

Steel

Materials used are steel piping to SABS 62, uncoated or galvanised typically for screwed systems up to 100mm (4”) diameter, Schedule 20, 40, 60, 80, etc., for welded systems from 50mm (2”) and greater

Your Direct Benefits

- At last get your compressed air systems’ cost efficiency ratio balanced. Engineered distribution systems, we guarantee the right pressure, volume, temperature and air quality.

- Save money on installation. Fewer direction changes compared to any other available compressed air distribution system.

- Get more for less. Isolation valves incorporated to maintain productivity and cut losses.

- Have your system reliable, available and maintainable. Sufficient unions or flanges used for maintenance and possible expansion of the system.

- Your most cost effective system available, short and long term.

- Spend less on air treatment. Reduced velocities = reduced filter regulator and lubricator maintenance = decreased cost for air treatment.

- You get an aesthetically pleasing installation that forms part of your factory display.

- Your system customised to your needs.